NEWS

High quality high performance excellent service

Search productSearch post

High quality high performance excellent service

To evaluate where to buy a laser diode or determine if a specific laser diode price is justified, one must first dismantle the device at the atomic level. The diode laser is not merely a semiconductor; it is a meticulously engineered optical resonator. Unlike LEDs, which rely on spontaneous emission, the laser diode laser operates on the principle of stimulated emission within a Gain Medium.

At the core of every high-performance diode laser is the Double Heterostructure (DH). By sandwiching a thin layer of a low-bandgap material (the active region) between two layers of a higher-bandgap material (cladding layers), manufacturers achieve both carrier confinement and optical confinement. This dual confinement is the prerequisite for achieving high efficiency. When a forward bias is applied, electrons and holes are injected into the active region. Because the cladding layers have a higher refractive index, they act as a waveguide, trapping the generated photons within the active layer.

The transition from a standard electronic component to a precision photonic tool occurs at the cleaved facets of the semiconductor crystal. These facets act as partially reflective mirrors, forming a Fabry-Pérot cavity. The round-trip gain must exceed the internal losses and the mirror losses for oscillation to occur. This tipping point is defined as the threshold current. For engineers looking to buy laser diodes, the threshold current stability across varying temperatures is the primary indicator of epitaxial quality.

When investigating the question of where can you buy diodes that offer industrial-grade longevity, the answer lies in the cleanroom, specifically the Metal-Organic Chemical Vapor Deposition (MOCVD) or Molecular Beam Epitaxy (MBE) process. The cost of a laser diode is heavily weighted toward the front-end epitaxial growth.

The thickness of the active quantum well—often only a few nanometers—must be controlled with atomic-layer precision. Any fluctuation in the thickness of the Gallium Arsenide (GaAs) or Indium Phosphide (InP) layers results in a shift in the emission wavelength. For high-precision applications, such as Raman spectroscopy or surgical lasers, a 2nm deviation can render a batch of chips useless. This yield rate is the invisible driver behind the laser diode price.

Furthermore, the management of strain in the crystal lattice is critical. By introducing “strained quantum wells,” manufacturers can modify the band structure to reduce the threshold current and increase the differential quantum efficiency. However, excessive strain leads to dislocations, which act as non-radiative recombination centers. These defects generate heat instead of light, leading to the dreaded Catastrophic Optical Damage (COD) at the laser facets.

A significant portion of the laser diode price is attributed to post-growth processing, specifically facet passivation and thermal management. The output facet is the most vulnerable part of the diode laser. Because the optical power density at the facet can reach several megawatts per square centimeter, even microscopic absorption can lead to localized melting.

Leading manufacturers employ E2 (Extraordinary Epitaxy) or specialized coating techniques to passivate the facets, effectively raising the COD threshold. This allows the laser diode laser to be driven at higher currents without the risk of sudden failure.

From a packaging perspective, the choice of heat sink is non-negotiable. Whether it is a C-mount, TO-can, or Butterfly package, the thermal resistance ($R_{th}$) determines the junction temperature ($T_j$). The rule of thumb in the industry is that for every 10°C increase in junction temperature, the lifetime of the laser diode is halved. Therefore, when you buy laser diodes, you are not just buying a chip; you are buying a thermal management solution.

For procurement officers asking where can you buy diodes that balance cost and performance, the market presents a wide spectrum. High-volume consumer-grade diodes (used in pointers or scanners) prioritize cost over spectral purity and MTTF (Mean Time to Failure). Conversely, industrial and medical-grade diode lasers are subjected to rigorous “burn-in” testing.

Burn-in testing involves running the diodes at elevated temperatures and currents for 48 to 96 hours. This process accelerates the failure of “infant” units with latent crystal defects. Only the survivors are shipped to the customer. This level of quality control (QC) is what separates a $5 component from a $500 precision instrument.

The following table outlines the technical characteristics of the primary materials used in laser diode manufacturing. These parameters directly influence the application range and the complexity of the manufacturing process.

| Material System | Wavelength Range (nm) | Common Applications | Thermal Conductivity (W/m·K) | Typical Wall-Plug Efficiency |

| InGaN/GaN | 375 – 520 | Bio-fluorescence, RGB Projection | 130 – 200 | 20% – 30% |

| AlGaInP | 630 – 690 | Medical Therapy, Leveling | 45 – 60 | 30% – 40% |

| AlGaAs/GaAs | 780 – 850 | Fiber Pumping, Hair Removal | 44 – 55 | 50% – 60% |

| InGaAsP/InP | 1300 – 1650 | Telecommunications, LiDAR | 68 – 75 | 30% – 45% |

| GaInAsSb | 2000 – 3000 | Gas Sensing, MWIR Countermeasures | 20 – 30 | 10% – 20% |

Client Background:

A European manufacturer of veterinary surgical equipment required a multi-wavelength laser diode module for a portable surgical unit. The device needed to combine 808nm (for deep tissue penetration) and 980nm (for high water absorption/hemostasis).

Technical Challenges:

The primary challenge was the thermal footprint. The portable unit had limited active cooling capacity. The client had previously used lower-priced diodes that suffered from “wavelength drift,” which reduced the surgical efficacy during prolonged procedures.

Technical Parameters & Settings:

Quality Control (QC) Solution:

We implemented a 100-hour burn-in at 45°C for every chip. Furthermore, we utilized Gold-Tin (AuSn) hard solder for chip-to-submount bonding. Unlike soft solders (Indium), AuSn prevents “solder migration” and “thermal fatigue,” ensuring the optical alignment remains stable even under cyclic loading.

Conclusion:

By switching from a price-centric procurement model to a technical-centric model, the client reduced their field failure rate from 4.2% to less than 0.1%. While the initial laser diode price was 20% higher than their previous supplier, the total cost of ownership (TCO) dropped by 35% due to reduced warranty claims and service calls.

When you decide to buy laser diodes, the integration process is as critical as the component itself. The driver electronics must be designed to suppress any transient current spikes. Even a microsecond of overcurrent can result in facet damage. Constant Current (CC) mode is mandatory, and for high-precision applications, a Thermoelectric Cooler (TEC) integrated with a PID controller is recommended to lock the wavelength.

Optical feedback is another factor. If the laser diode laser is used in a system with reflective surfaces, an optical isolator must be used. Back-reflections into the laser cavity cause “relative intensity noise” (RIN) and can eventually destroy the diode facets.

Q: Why does the laser diode price vary so significantly between 808nm and 450nm diodes?

A: The price is driven by material maturity and substrate costs. GaAs-based diodes (808nm) have been refined for decades. GaN-based diodes (450nm) involve more complex epitaxial growth on sapphire or GaN substrates, which have higher defect densities and lower growth yields, thus increasing the cost per watt.

Q: Can I drive a diode laser with a standard DC power supply?

A: It is highly discouraged. Standard power supplies often have high ripple and lack current-limiting protection against spikes during power-on/off. A dedicated constant-current laser driver is essential to protect the delicate P-N junction.

Q: How does the “emitter width” affect the laser diode buy decision?

A: Single-mode diodes have narrow emitters (typically <5µm) and provide high beam quality (low $M^2$), but limited power. Multi-mode (broad-area) diodes have emitters ranging from 50µm to 200µm, allowing for much higher power outputs but with lower brightness and higher divergence. Your choice depends on whether your application requires focusability or raw power.

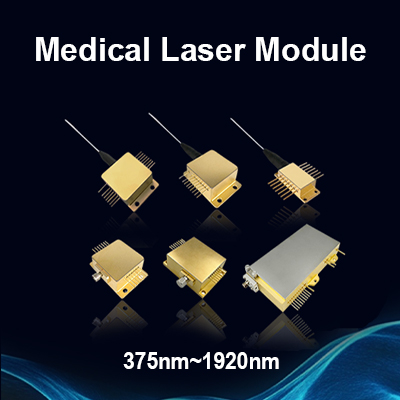

Q: Where can you buy diodes with certified longevity for medical use?

A: Seek manufacturers that provide full traceability and LIV (Light-Current-Voltage) test reports for every unit. Certifications like ISO 13485 are indicators that the manufacturer follows the stringent quality management systems required for medical-grade components.

The industrial demand for high-intensity light has driven the diodelaser from a milliwatt-scale signal device to a multi-kilowatt energy source. In the technical procurement landscape, whether an engineer searches for a diodlaser, a lazer diode, ...

View detailsThe relentless demands of modern industry—from aerospace to ship repair—require surfaces to be impeccably clean, free of rust, paint, and contaminants before welding, coating, or inspection. For generations, this crucial step relied on abrasive b...

View detailsIn the world of photonics, the terms laser diode and laser module are often used interchangeably by buyers, yet they represent fundamentally different stages of engineering integration. For a manufacturer, choosing between a standalone component ...

View detailsWhen an engineer seeks to buy laser diodes, the immediate focus is often on peak power and wavelength. However, the true metric of a high-performance diode laser is its degradation rate under high-injection conditions. Understanding the physics ...

View details