NEWS

High quality high performance excellent service

Search productSearch post

High quality high performance excellent service

In the world of photonics, the terms laser diode and laser module are often used interchangeably by buyers, yet they represent fundamentally different stages of engineering integration. For a manufacturer, choosing between a standalone component and a fully integrated system is the pivot point between project failure and scalability.

This guide explores the technical architecture, thermal management, and practical application of these light sources in modern industry.

Before asking why your laser system is failing or underperforming, we must ask: Is the laser diode being treated as a complete light source? It is not.

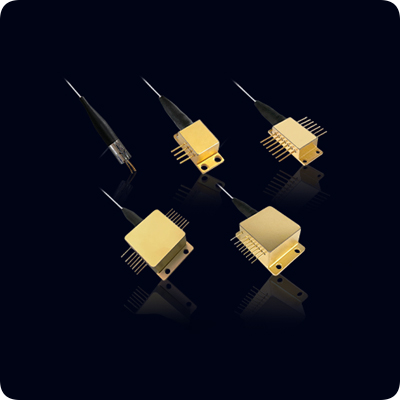

A laser diode is a semiconductor p-n junction that emits coherent light through stimulated emission. It is the “engine” of the system. However, in its raw form (such as a TO-can or butterfly package), it lacks:

A laser module is the “vehicle” that houses the engine. It integrates the laser diode with a drive circuit (APC or ACC), collimating optics (aspheric lenses), and a housing designed for heat dissipation.

Expert Insight: For industrial integration, using a pre-calibrated laser module reduces time-to-market by eliminating the need for complex internal optical alignment and PCB design.

| Feature | Laser Diode (Component) | Laser Module (Integrated System) |

| Driver Circuitry | None (Requires external PCB) | Built-in (Constant Current/Power) |

| Beam Quality | Highly Divergent | Collimated or Focused |

| Heat Management | Dependent on external mounting | Integrated aluminum/copper housing |

| Ease of Use | High technical barrier | Plug-and-Play |

| Cost | Low per unit | Higher (includes optics/electronics) |

To rank well and serve your customers, your content must address the specific “pain points” of laser integration.

In applications like Raman spectroscopy or precision sensing, a laser diode’s wavelength shifts with temperature (typically $0.3nm/^{\circ}C$). A professional laser module often incorporates a TEC (Thermoelectric Cooler) to lock the wavelength, ensuring the “laser diode laser” output remains consistent regardless of ambient conditions.

Why does the beam spot size matter?

Client Profile: A Tier-1 automotive sensor developer in Germany.

The Problem: The client was using raw 905nm pulsed laser diodes for their prototype LIDAR systems. They reported a 15% failure rate during environmental stress testing and inconsistent detection ranges across different units.

The “Ask if it is so” Analysis:

We first asked: Is the diode failing due to inherent defects, or is it the integration?

Upon inspection, we found that the client’s manual soldering of the TO-can leads was inducing thermal stress. Furthermore, their external driver circuit had a 2ns jitter, which skewed the Time-of-Flight (ToF) calculations.

The Solution:

We transitioned the client to a customized laser module with the following specs:

The Result:

To ensure your laser diode laser reaches its rated 10,000+ hour lifespan, follow these professional protocols:

While infrared and red diodes dominate the market, high-power blue laser diodes (445nm – 455nm) are transforming the industry. Due to the higher absorption rate of blue light in non-ferrous metals like copper and gold, these modules are becoming the gold standard for battery manufacturing and jewelry welding.

Choosing between a laser diode and a laser module depends on your internal engineering capability. If you have the facilities to handle micron-level alignment and precision electronic design, the diode offers the lowest BOM cost. However, for most industrial applications, a fully engineered module provides the reliability and consistency required for global scaling.

The evolution of the modern laser module begins not with a lens or a housing, but within the crystalline lattice of a direct bandgap semiconductor. To understand why a professional Semiconductor Laser outperforms consumer-grade alternatives, one...

View detailsThe development of the high power semiconductor laser has transitioned from simple light generation to the management of extreme energy densities. To understand a high powered laser diode, one must look beyond the macro-scale package and into th...

View detailsIn the hierarchy of photonic components, the 1064nm single mode fiber coupled laser diode occupies a unique position. While multi-mode diodes are valued for their raw power, single-mode modules are the architects of precision. The fundamental va...

View detailsIntroduction: Seeing the Invisible In oncology and dentistry, early detection is the only metric that matters. Traditional white-light examination relies on the human eye’s ability to discern morphological changes—a lump, a discoloration, or a ...

View details