NEWS

High quality high performance excellent service

Search productSearch post

High quality high performance excellent service

Introduction: The Engine Room of Dentistry

In our previous discussion (Is Your Dental Practice Missing Out on Diode Precision?), we explored the clinical outcomes of laser surgery. But for medical device engineers, biomedical technicians, and OEM manufacturers, the clinical result is merely the final output of a complex chain of electronics.

The heart of any medical laser system is the laser diode module. However, a module is only as good as the current controlling it. The symbiotic relationship between the laser diode and driver is the single most critical factor in device safety, longevity, and FDA/CE compliance. This article deconstructs the engineering required to build a reliable dental diode laser.

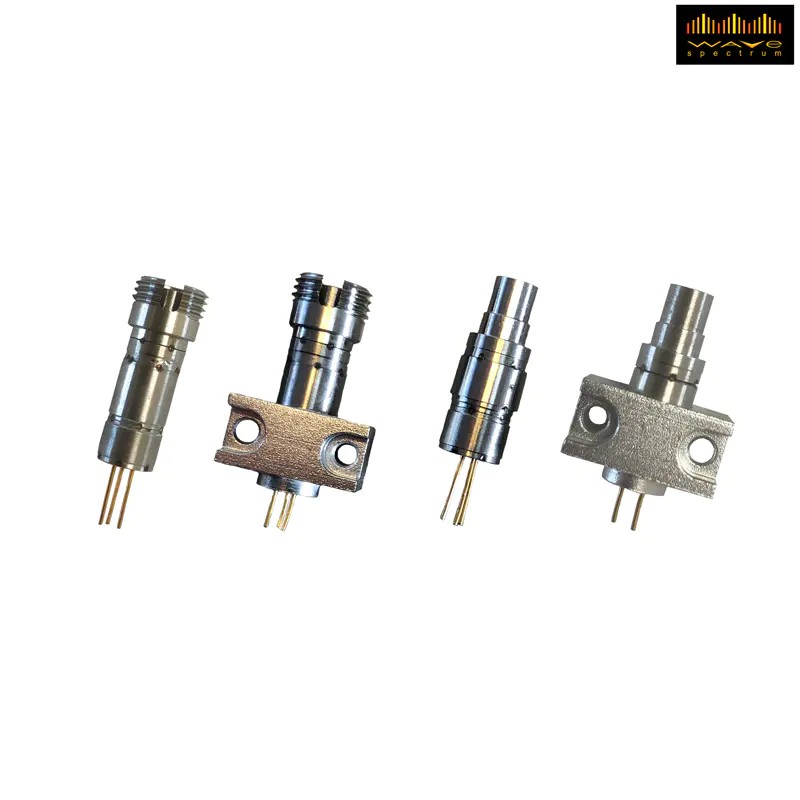

The Anatomy of a High Power Laser Diode Module

A high power laser diode is a semiconductor device that converts electrical energy into coherent light. In dental applications, we typically operate in the Near-Infrared (NIR) spectrum (808nm to 1064nm).

Unlike telecommunication lasers, a dental laser diode module requires massive photon density to ablate tissue. This introduces the “Thermal bottleneck.”

The Unsung Hero: The Laser Diode and Driver

You cannot simply plug a laser diode into a wall outlet. It requires a constant current source, not constant voltage. This is the job of the laser diode and driver.

Key Technical Requirements for Medical Drivers:

Technical Case Study: Failure Analysis of a Generic Unit (This section mimics an engineering failure report)

Incident Report: #ENG-2024-88 Device Type: 10W Portable Dental Diode Laser (Imported Generic Brand). Problem: Device failing to initiate fiber tips; User reports “Fluctuating power” and “Device gets hot to touch.”

Forensic Disassembly & Analysis:

- Component A: The laser diode module was inspected. The collimating lens showed signs of fogging due to outgassing from cheap thermal paste.

- Component B: The laser diode and driver circuit was analyzed via oscilloscope.

- Findings:

- Ripple Current: The driver exhibited a 15% ripple current (Standard should be <1%).

- Thermal Management: The diode was mounted on a passive aluminum block with no TEC (Thermoelectric Cooler).

The Failure Chain:

- As the dentist used the laser for a long procedure (full mouth decontamination), the passive cooling failed.

- The diode junction temperature rose.

- The driver, lacking active feedback loops, continued to push current.

- The combination of heat and ripple current caused “Facial Catastrophic Optical Damage” (COD) to the diode emitter.

- Result: The optical output dropped from 10W to 2W, rendering the device useless.

Correction Strategy: Replacing the unit with a module featuring an integrated NTC thermistor and a PID-controlled driver solved the issue, stabilizing output to ±0.1W.

Advanced Applications: Fiber Coupling Efficiency

For a dental diode laser to be effective, the light from the emitter must enter a fiber optic core that is often only 200 to 400 microns wide.

Future Trends: Blue Light and Multi-Wavelengths

The future of the laser diode module industry is hybrid packaging. We are now seeing modules that combine 450nm (Blue – for superior cutting efficiency without heat) and 980nm (Infrared – for deep disinfection) into a single output. This requires a sophisticated multi-channel laser diode and driver capable of mixing wavelengths in real-time.

Summary for Buyers and Engineers

When designing or purchasing a dental diode laser, specifications on a datasheet are not enough. You must verify the quality of the laser diode and driver integration. Stability, thermal management, and protection circuits are what differentiate a medical device that lasts 5 years from one that fails in 6 months. A robust high power laser diode system is an investment in reliability.

Introduction: The Shift from Steel to Light In the modern landscape of oral surgery, patient expectation has shifted. The tolerance for post-operative pain and extended healing times is at an all-time low. For the progressive dental clinic, the...

View detailsIn the industrial photonics sector, the move toward higher power density is the defining challenge of the decade. While single-mode diodes excel in spatial coherence, the high power fiber coupled laser diode is the engine of the industry, drivin...

View detailsThe architecture of a Multi-mode Laser Diode is fundamentally designed to circumvent the power limitations inherent in single-mode structures. While a single-mode diode is constrained by a narrow waveguide to maintain a $TEM_{00}$ spatial profil...

View detailsIn the hierarchy of semiconductor photonics, the Multi-mode Laser Diode represents the pinnacle of raw energy density. While single-mode emitters are the surgeons of the optical world—valued for their spectral purity and diffraction-limited focus...

View details