NEWS

High quality high performance excellent service

Search productSearch post

High quality high performance excellent service

The 21st century industrial landscape is defined by precision, speed, and efficiency. For decades, these demands were met by bulky, complex laser systems relying on gas or solid-state mediums. However, an unassuming, wafer-thin technology—the laser diode—has quietly spearheaded a revolution, fundamentally altering how products are manufactured, measured, and transmitted. This miniature semiconductor source, often packaged into a robust laser module, has become the workhorse of high-power industrial applications, telecommunications, and advanced sensing.

The question is no longer whether lasers are essential to modern manufacturing, but whether the inherent advantages of the compact laser diode laser system—reliability, energy efficiency, and scalability—have truly relegated traditional industrial lasers to history. The answer lies in the dramatic shift toward fiber-coupled systems and integrated modules that offer unprecedented control and power density. This article will delve into the technical underpinnings of the laser diode, explore the functionalities of the complete laser module, and ultimately demonstrate, through a groundbreaking automotive industry case study, how the laser diode laser has become the single most transformative element in industrial optimization. We will prove that its impact is not just incremental, but foundational to achieving the next level of industrial productivity and cost reduction, challenging the very notion of large-scale manufacturing requirements.

At its core, a laser diode is a semiconductor device that generates coherent light through the process of stimulated emission. Unlike conventional LEDs, the laser diode utilizes a P-N junction within a carefully designed gain medium (often Gallium Arsenide or Indium Phosphide) to create a resonant cavity, allowing photons to multiply and emerge as a highly collimated, monochromatic beam. This solid-state design is the basis of its durability and efficiency.

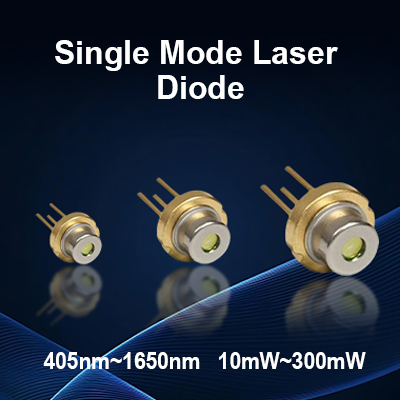

Key technical parameters differentiate a high-quality laser diode suitable for industrial use:

The transition from a raw laser diode chip to a functional device marks the difference between the component and the system. When several high-power laser diode arrays are combined through advanced beam steering, they form the optical engine of a powerful laser diode laser system, offering multi-kilowatt-level output in a package far smaller than any solid-state or gas alternative. This modularity is a critical advantage, ensuring system resilience and ease of maintenance. The energy conversion efficiency, known as “wall-plug efficiency,” of the laser diode laser often exceeds $40%$, a dramatic improvement over older laser types.

The raw laser diode cannot function effectively in an industrial setting without its peripheral systems—this is where the laser module comes in. A laser module is an integrated subsystem designed to optimize the performance, manage the thermal load, and shape the output beam of one or more laser diode emitters. This packaging is what turns a fragile semiconductor into an industrial tool.

The reliability of a modern laser diode laser is directly proportional to the quality and integration of its laser module. This standardization and compactness have accelerated their deployment across diverse fields, from micro-machining of semiconductors, where precision is paramount, to large-scale material processing like welding and cladding, where power and uptime are critical.

Is a small laser diode laser system robust enough for high-speed car production? The best way to answer the opening question is to examine a scenario where efficiency and reliability are non-negotiable: high-speed automotive production.

The evolution of the laser diode is relentless, focusing on power scaling, miniaturization, and spectral purity. Future trends include:

The core question posed—whether the laser diode laser has transformed modern industry—is decisively answered by the evidence. It has moved beyond being a mere component to becoming the defining technology of precision manufacturing. The reliability and efficiency demonstrated in the Volkswagen case study are not anomalies but the new expected performance standard of a well-engineered laser module integrated into an industrial system.

The economic and ecological advantages are undeniable: dramatically lower energy consumption, vastly reduced maintenance costs, and superior process control, all leading to a higher quality product at a lower cost. As semiconductor technology continues to mature, the power density, efficiency, and operational lifespan of the laser diode will only increase. For manufacturers seeking a competitive edge defined by precision and sustainability, the adoption of robust, fiber-coupled laser diode laser systems is not an option—it is a mandatory step toward future proofing operations and maintaining global competitiveness. The age of the bulky, inefficient laser is over; the era of the compact, powerful laser diode is here to stay, illuminating the path for Industry 5.0.

To understand the operational excellence of a modern laser diode, one must look beyond the macroscopic housing and into the microscopic architecture of the semiconductor heterostructure. At its core, the laser diode is a triumph of quantum mecha...

View detailsIntroduction: The Shift from Steel to Light In the modern landscape of oral surgery, patient expectation has shifted. The tolerance for post-operative pain and extended healing times is at an all-time low. For the progressive dental clinic, the...

View detailsThe development of high-performance visible-spectrum laser diodes represents one of the most significant achievements in solid-state physics. For an OEM integrator, selecting between a 520nm laser diode, a 488nm laser, or a uv laser diode is not...

View detailsThe journey of a high-performance semiconductor light source begins long before the final assembly in a China laser diode factory. It starts with the calculation of the Schrödinger equation within the context of a periodic crystal potential. To f...

View details