뉴스

고품질 고성능 우수한 서비스

제품 검색게시물 검색

고품질 고성능 우수한 서비스

The evolution of the modern 레이저 모듈 begins not with a lens or a housing, but within the crystalline lattice of a direct bandgap semiconductor. To understand why a professional Semiconductor Laser outperforms consumer-grade alternatives, one must look at the carrier recombination dynamics within the active region. Unlike gas or solid-state lasers, the semiconductor variant relies on the injection of electrons and holes into a double-heterostructure or quantum well (QW) design.

When a forward bias is applied to the P-N junction, electrons from the N-side and holes from the P-side flow into the active layer. This layer, typically composed of Gallium Arsenide (GaAs), Indium Phosphide (InP), or Gallium Nitride (GaN), is engineered to have a narrower bandgap than the surrounding cladding layers. This creates a “potential well” that traps carriers, significantly increasing the probability of radiative recombination.

Stimulated emission occurs when a photon with energy precisely matching the bandgap $E_g = h\nu$ triggers an electron to drop from the conduction band to the valence band, emitting a second photon that is coherent in phase, frequency, and direction. In a high-end 레이저 모듈, the precision of this bandgap engineering determines the spectral linewidth and the temperature stability of the output.

The optical feedback required for laser oscillation is provided by the cleaved facets of the semiconductor crystal itself, forming a Fabry-Pérot cavity. However, the high power densities at these facets—often reaching Megawatts per square centimeter—necessitate advanced passivation techniques. Without proprietary facet coatings, a laser for sale in the industrial market would succumb to Catastrophic Optical Damage (COD) within hours of operation.

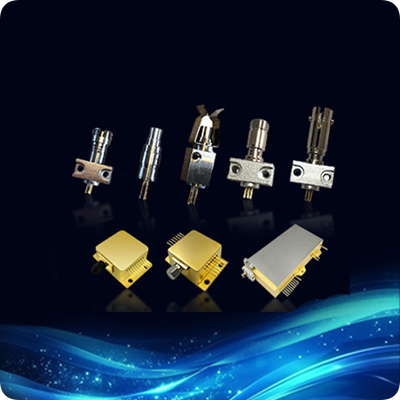

A 레이저 모듈 is far more than a diode in a tube. It is a complex optomechanical system designed to manage heat, stabilize current, and shape the highly divergent raw beam of a Semiconductor Laser. In technical procurement, the terms 레이저 모듈, laser modul, or the occasionally used Latinate laser modulo all refer to this integrated solution.

의 원시 출력 레이저 다이오드 is inherently asymmetric. Due to the narrow dimensions of the emitting aperture (often only 1 micrometer high), diffraction causes the beam to diverge rapidly—a phenomenon known as the “Fast Axis” and “Slow Axis” divergence.

고성능 레이저 모듈 utilizes aspheric glass lenses to correct this. For multi-mode emitters used in high-power applications, Fast-Axis Collimation (FAC) lenses are micro-optics glued directly onto the diode submount with micron-level precision. The choice of optical material—whether it is high-refractive-index N-SF11 glass or molded plastic—dictates the beam’s M² factor (beam quality) and long-term power stability.

효율성 Semiconductor Laser typically ranges from 30% to 60%. The remaining energy is converted into heat. Because the wavelength of a laser diode shifts with temperature (typically 0.3nm/°C for GaAs), maintaining a constant junction temperature is critical.

Industrial 레이저 모듈 utilize copper submounts with high thermal conductivity and, in many cases, integrated Thermoelectric Coolers (TEC). By monitoring a built-in Negative Temperature Coefficient (NTC) thermistor, the driver circuit can dynamically adjust the TEC current to maintain sub-degree temperature stability. This is the technical differentiator between a generic component and a professional-grade module.

When an engineer searches for a laser for sale, the “unit price” is often a deceptive metric. The true cost of a laser system is dictated by the Mean Time To Failure (MTTF) and the integration overhead. A lower-tier Semiconductor Laser may save $50 initially, but if its beam pointing stability causes a failure in a medical surgical robot or a LIDAR sensor, the warranty and reputation costs can reach five figures.

If a 레이저 모듈 uses low-quality optics, the beam divergence will increase over time due to thermal expansion or lens degasification. In industrial cutting or medical ablation, this leads to a larger spot size, lower energy density, and ultimately, a failed process. The “System Cost” includes the replacement labor and the downtime of the end-user’s facility.

The PN junction of a 레이저 모듈 is extremely sensitive to electrostatic discharge (ESD) and current spikes. A robust module incorporates a “Soft Start” circuit and Transient Voltage Suppressors (TVS). If an OEM chooses a cheap laser modul lacking these protections, the “Infant Mortality” rate of their products will rise, leading to a disastrous cycle of field repairs.

To provide a clear picture of the engineering gap, the following table compares the typical parameters of an industrial-grade 레이저 모듈 (optimized for durability) against a standard consumer-grade unit.

| 기술 매개변수 | Industrial Grade (laserdiode-ld.com standard) | Consumer/Hobbyist Grade |

| 파장 허용 오차 | ±3 nm (customizable to ±1 nm) | ±10 nm to ±20 nm |

| Operating Life (MTTF) | 10,000 to 20,000 hours | < 3,000 hours |

| Beam Divergence (Full Angle) | < 0.5 mrad (with collimation) | 1.5 – 3.0 mrad |

| 열 관리 | Active TEC / Copper Heatsink | Passive Aluminum / No Heatsink |

| Optical Coating | High-Damage Threshold AR Coating | Standard Grade or Uncoated |

| Power Stability (8h) | < 1% RMS | > 5% – 10% |

| Driver Protection | ESD, Over-temp, Reverse Polarity | Basic Current Limiting |

Beyond the core keywords, three critical technical domains must be addressed to fully understand the current state of Semiconductor Laser technology:

A European manufacturer of dental surgical equipment required a high-reliability 레이저 모듈 for soft-tissue ablation. The device needed to be handheld, battery-operated, and capable of constant power output for 15-minute procedures without overheating.

Each 레이저 모듈 underwent a 48-hour “Burn-in” test at 40°C to weed out early-life failures. Spectral testing was performed using a high-resolution spectrometer to ensure no mode-hopping occurred under varying current levels. The beam profile was mapped using a CCD camera to verify the absence of “hot spots” that could burn tissue unevenly.

By selecting a high-spec Semiconductor Laser with integrated monitoring, the client reduced their assembly time by 30%—as they no longer needed to calibrate external optics. The field failure rate dropped from 4.5% (with their previous supplier) to less than 0.2% over a two-year period. This transition proved that the upfront cost of a superior 레이저 모듈 is recovered through reduced warranty claims.

In a globalized market, the search for a laser for sale often leads to marketplaces flooded with unverified specifications. For an OEM, the vetting process must focus on the following engineering data:

The technical superiority of 레이저 모듈 from dedicated manufacturers like laserdiode-ld.com lies in the mastery of these micro-details. Whether the term used is laser modul or 레이저 모듈, the underlying requirement remains the same: the reliable conversion of electrons into precise photons.

Q1: What is the main cause of sudden failure in a Semiconductor Laser module?

A: Most sudden failures are caused by Electrostatic Discharge (ESD) or Catastrophic Optical Damage (COD). COD occurs when the power density at the facet is so high that the semiconductor material melts, often triggered by a current spike or a speck of dust on the facet.

Q2: How does the “Fast Axis” collimation affect the quality of a laser module?

A: Because the emitting area is so thin, the beam diverges very quickly in one direction (the Fast Axis). If the FAC lens is not aligned within sub-micron tolerances, the resulting beam will be astigmatic, making it impossible to focus the laser into a small, clean spot.

Q3: Why are some laser modules significantly more expensive even if they have the same power rating?

A: The price difference usually reflects the quality of the internal diode “binning” (selecting only the most stable diodes), the complexity of the driver circuit (protection and stability), and the precision of the optical collimation. Higher-priced modules offer lower M² values and longer lifetimes.

Q4: Can a laser module’s wavelength be adjusted?

A: To a limited extent, yes. By changing the operating temperature via a TEC, the wavelength can be shifted slightly (approx. 0.3nm per degree Celsius). This is commonly used in “tuning” the laser to a specific absorption peak of a gas or a solid-state gain medium.

산업 제조 분야의 경쟁 환경에서, 원시 레이저 다이오드에서 기능성 레이저 모듈로의 전환 과정은 종종 오해받습니다. 많은 구매 관리자들이 "왜 내 레이저의 빔 품질이 시간이 지남에 따라 저하되는가?" 또는 "왜..."라고 묻습니다.

상세 정보 보기고위험 산업 제조 분야에서 정밀도는 단순히 절삭 정확도만을 의미하지 않습니다. 수천 시간에 걸쳐 빔의 일관성을 유지하는 것이 핵심입니다. 수년간 업계는 번거로운 거울 기반 전달 시스템이나 직접 다이오드 어레이에 의존해 왔는데...

상세 정보 보기현대 웨어러블 기기(스마트워치, AR 안경, TWS 이어버드)의 조립 과정에서 접착제와 초음파 용접이 점차 사라지고 있다. 접착제는 경화 속도가 너무 느리고, 초음파 진동은 민감한 MEMS 마이크로폰과 자이로스코프를 손상시키기 때문이다. 표준은 ...

상세 정보 보기대다수의 대중에게 레이저 다이오드는 바코드 스캐너나 DVD 플레이어의 광원으로 인식됩니다. 그러나 의료 진단이라는 고위험 분야에서 이 소형 반도체는 정밀성의 핵심 동력원으로 진화했습니다.

상세 정보 보기